The foundry business underpins industry

Casting is the backbone of the industry with many casting parts, including automobiles and airplanes, called the rice of industry, supporting a rich society.

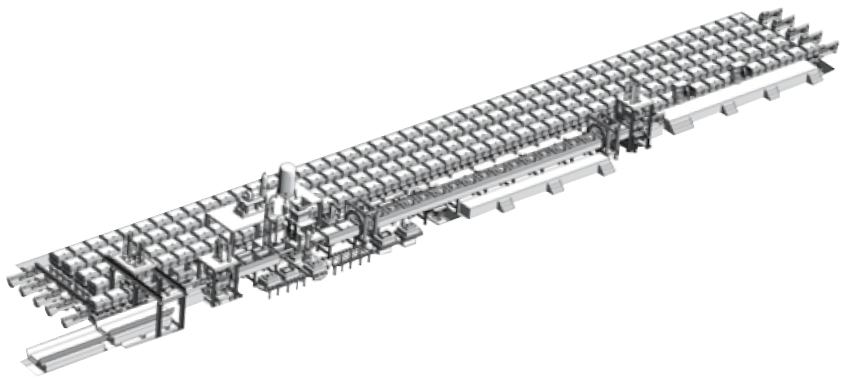

Since its establishment in 1970, Korea Sinto Industries has been the world's number one casting plant manufacturer in terms of product lineup, market share, technology development, maintenance, and supply of parts and consumables, focusing on various types of molding machines based on its rich experience and know-how. In addition, with production and sales bases around the world, we provide a global perspective on the processing of production for customers with overseas operations.

We will continue to support the production of higher quality castings by developing high-value-added devices and processes, while considering the environment and safety.