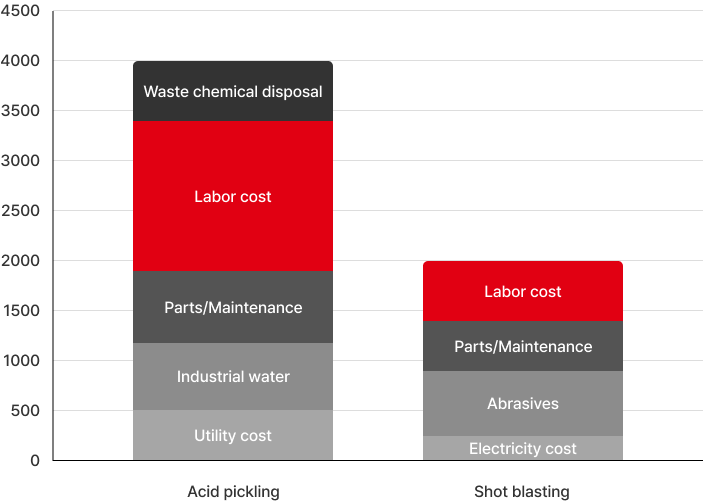

Product quality equivalent to one

by acid pickling

-

Headquarters / Mechanical

- Tel. +82-53-615-4901

- FAX. +82-53-615-4901

-

SHOTBALL

- Tel. +82-53-615-4901

- FAX. +82-53-615-2119

COPYRIGHT (C) KOREA SINTO CO,.LTD ALL RIGHTS RESERVED