Mechanization and automation

-

Headquarters / Mechanical

- Tel. +82-53-615-4901

- FAX. +82-53-615-4901

-

SHOTBALL

- Tel. +82-53-615-4901

- FAX. +82-53-615-2119

COPYRIGHT (C) KOREA SINTO CO,.LTD ALL RIGHTS RESERVED

COPYRIGHT (C) KOREA SINTO CO,.LTD ALL RIGHTS RESERVED

Use of sand core is mandatory to create cavities in the casting.

There are various problems by remaining sand in the casting.

Cleaning of sand is a must.

Mechanization and automation

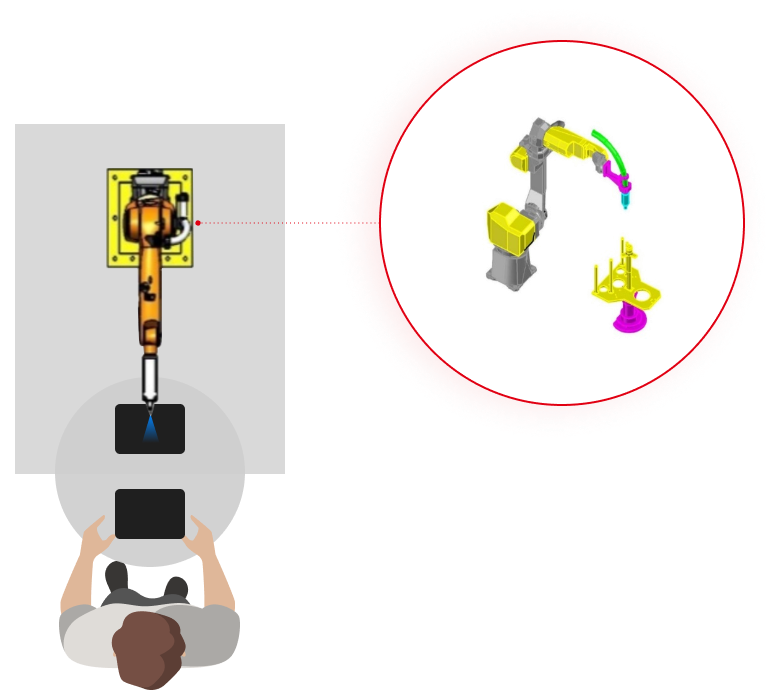

Combination of “Air Blast” and “Robot” solves the problem.

Robotic Air Blast System “MYR”

No use of chemical solution

Not necessary of waste water system

No electricity for heating

No use of chemical solution

Outsourcing cost elimination

Easy automation and labor reduction

Leave off of high temperature environment

Case 01Automation reduces labor and manual work.

Case 02Accurate spot processing by programming.

Target spots can be accurately blasted by robot.

By using interior nozzle, deep spots can be blasted.

Contributing quality improvement

Demonstration video

Interior nozzle