-

Headquarters / Mechanical

- Tel. +82-53-615-4901

- FAX. +82-53-615-4901

-

SHOTBALL

- Tel. +82-53-615-4901

- FAX. +82-53-615-2119

COPYRIGHT (C) KOREA SINTO CO,.LTD ALL RIGHTS RESERVED

COPYRIGHT (C) KOREA SINTO CO,.LTD ALL RIGHTS RESERVED

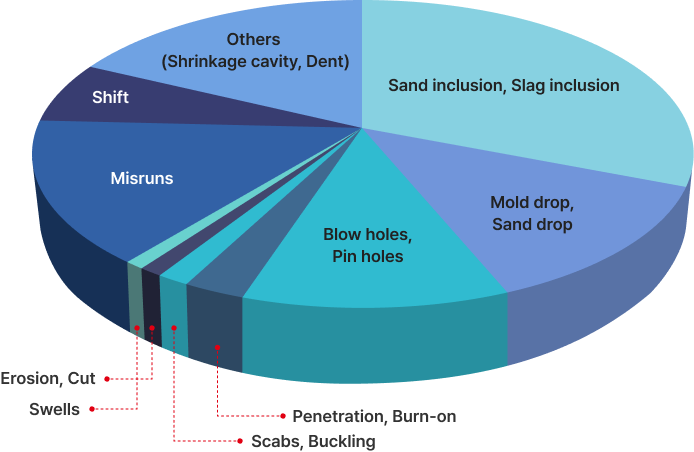

Casting defect rate by reason (%)

Q. Are you having trouble with defective castings?

For eliminating casting defects

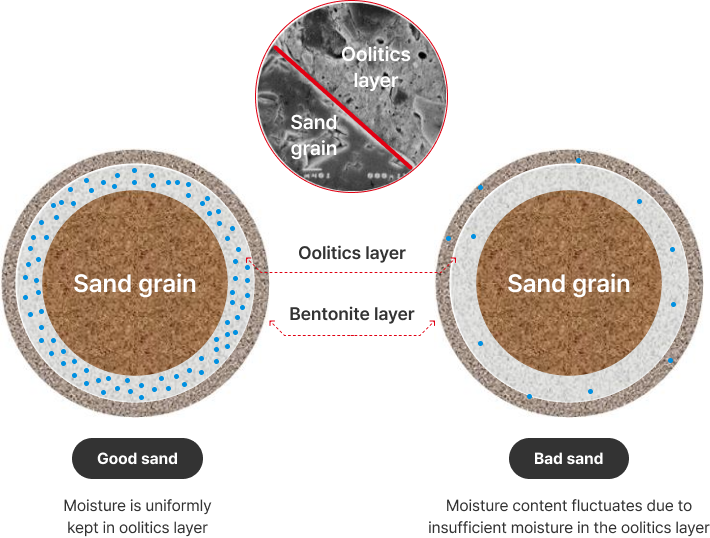

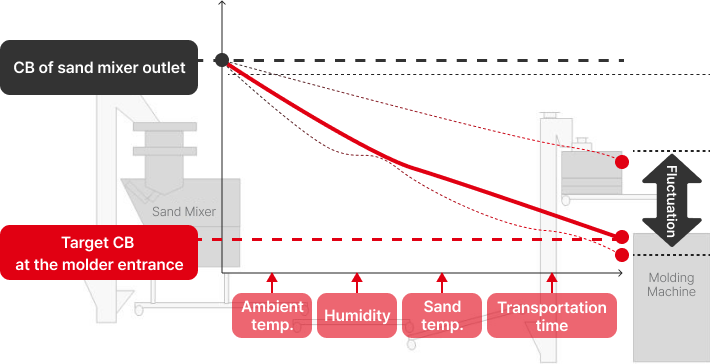

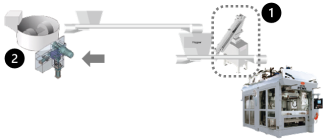

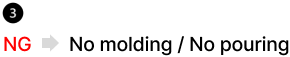

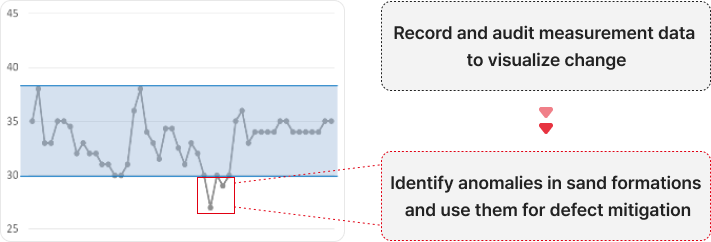

Sand properties change during transportation from mixer to molding machine by External Factor; such as Ambient temperature, Humidity, Sand temperature, Lapsed time, etc.

It is critical to control sand properties at the molding machine to prevent casting defects.

IDST automatically measures 5 sand properties

Change the settings in the mixer according to the data obtained from the molding machine by changing the settings in the mixer according to the data obtained from the molding machine.

| MODE 1 | MODE 2 |

|---|---|

| 75 sec/cycle approx. | 30 sec/cycle approx. |

| CB | CB |

| Moisture | Moisture |

| Sand temperature | Sand temperature |

| Permeability | |

| Compressive strength |

Belt size (Belt conveyor shall have rated feed function)

Guide width: 350mm and over / Sand thickness: 70mm and over

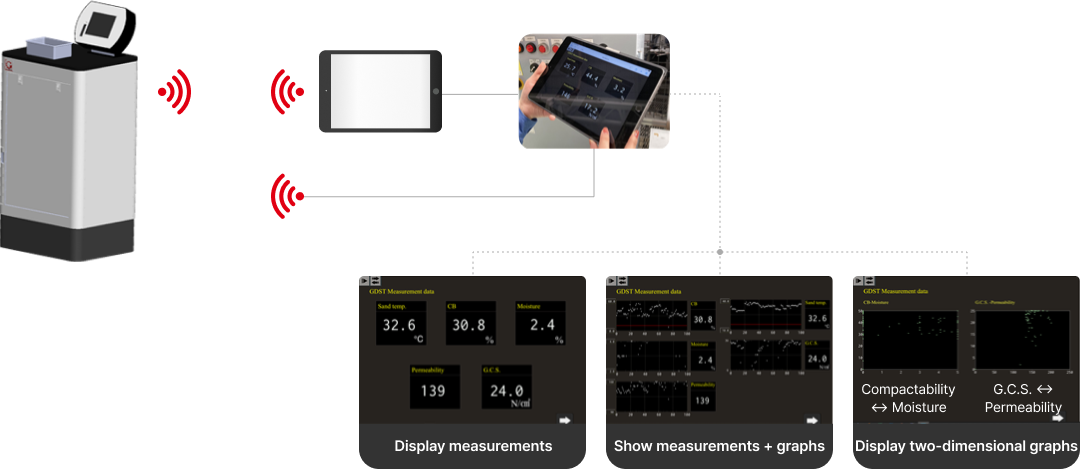

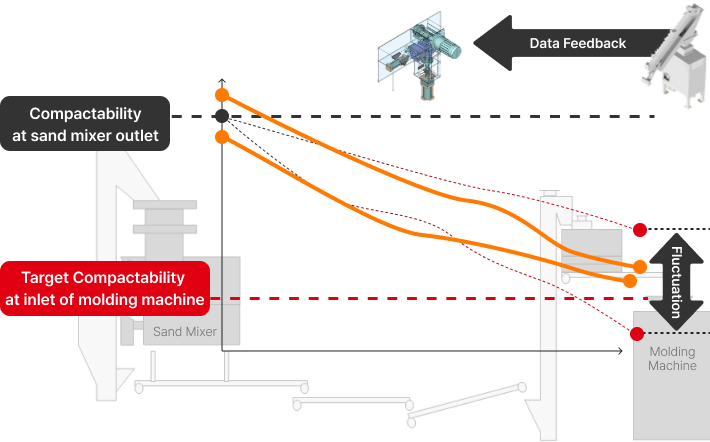

Sand property management by digital data

Accurate measurement

Integrated measurement in one unit

Reduced labor for sand formation measurements

San Drama Standard Preparation of the test piece

Moisture meter

Permeability tester

Compressive strength tester

About 20 minutes total for all sand testers

Measurement by anyone, anytime, anywhere

Example) near the molding machine, near the kneaderGEST 약 40초

Send measurements to remote tablets

and PCs via WI-FI Data can also be sent

in CSV format